Medical Marijuana Testing and Labeling Process

Medical Cannabis testing and labeling allows consumers to understand what they are buying and make informed decisions about purchasing medical marijuana.

Accurate testing is important for patients who are looking for specific therapeutic effects from their medicine.

Medical marijuana products available in the market vary on the basis of their THC and CBD content. Some of these products are mixed with other compounds like alcohol or herb extracts which further differentiates them from one another.

State laws require that manufacturers must clearly label the content, potency and residual levels of their products for general awareness.

Consumers looking to purchase medical marijuana might be wary of the products in the market. We are giving a brief overview of the extraction process as well as the testing and labeling mandated by state legislation that should be followed by medical marijuana pharmacies and laboratories.

Cannabis Extraction

Cannabis is usually extracted in a concentrated form for medical use. The concentrate is more potent than regular cannabis buds and the smell, taste and effects are magnified.

The process of extraction is quite complex, requires laboratory equipment and could be hazardous to health if done incorrectly. The extracts are either in dried form or oils.

Kief

This is a basic, dry form of cannabis extract. Getting this extract involves breaking the trichomes away from a dried sample of the plant and pressing it against filtering screen to. It is considered a low quality extract although it is possible to get slightly better quality with laboratory equipment. THC content can range from 20 to 60.

Dry Sieve

Dry Sieve is a slight modification of Kief and more refined. The difference is that dry sieve gets run through filter screens multiple times unlike Kief. The quality of the final product is dependent on the amount of trichome stalks and plant matter in the mix.

The process is meant to get the most perfect trichome gland heads and none of the gland stems or plant matter which usually happens with the Kief extraction method.

Hash

Hash is probably one of the oldest extractions of cannabis that has been around for centuries. There are many processes for making hash from cannabis.

A common method is ice water extraction where the trichome heads are isolated from the rest of the plant and stalks that carry little medicinal value. Drying the separated hash requires careful work. If not done properly the hash can become moldy and develop microscopic bacteria and fungi that could be harmful to the consumer. This is why the process is best completed in a laboratory with trained extractors.

Butane Hash Oil

This extract is also commonly known as BHO. It is one of the most widely produced and used cannabis oils in the medical marijuana industry. BHO is made with Butane as the main solvent. The potency of the extract can be varied based on the amount of butane used, the temperatures applied to the drug and the consistency of the final product.

This extraction method allows THC levels of up to 80% and even 90%. This makes BHO one of the most potent and popular choice for patients.

CO2 Oil

Carbon dioxide is a naturally occurring gas and it can be very useful for extraction because it leaves behind no residue. The gas can be converted into liquid form when put under high pressure and already used in water treatment, food processing, herbal and dry cleaning sectors.

CO2 can also be used for extraction of CO2 oil from cannabis. Supercritical (or liquid) form of carbon dioxide is passed through a high pressure vessel with cannabis buds. This creates a mixture of CO2 and cannabis. The plant matter is then separated using a filter and allowed to return to normal pressure. Excess CO2 evaporates and the rest is dissolved into the cannabinoid extract.

Supercritical CO2 oil is considered cleaner and easier to use in vapor pens and less risky as it is non-flammable. It is usually more expensive than BHO.

Rosin

Rosin is becoming popular in the medical marijuana industry. It is easier and quicker to extract, low cost and creates a decent quality hash without any solvent. It requires less equipment than other methods of extraction as well.

The method is quite new and produces a solvent-less hash. This is done by using steam pressure to extract a terpene-rich, cannabinoid filled oil from the trichome heads, dry sift and water hash. The process is designed to burst open the buds and force the oil out which give a full melt hash.

Some of the cannabis extraction methods leave the final product with residual solvents and laboratories perform tests to ensure any harmful substances are removed to create a safe and usable product.

Common Laboratory testing for Cannabis

Marijuana testing for medical use is carried out in laboratories. It is a detailed process that involves a comprehensive analysis of cannabis extract for its chemical composition, potency, residual solvents, contamination and terpenes.

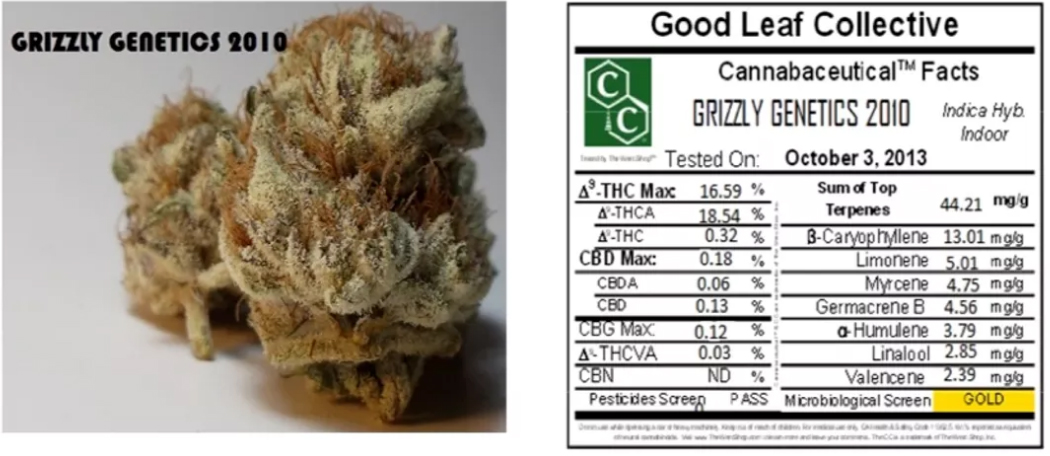

Each state allowing marijuana purchase for medical purpose puts strict conditions and restrictions on the laboratories to ensure the highest standard of testing is done before commercial sale. The state of California for instance requires batch tests to report measurements of the known cannabinoids, such as THC, CBD, CBG and CBN in a sample.

The chemical concentration gets reported in milligrams up to 3 significant figures. The laboratory is also required to calculate the dry weight percent of cannabinoids in the batch.

Further tests mandated for medical marijuana are detailed below

Residual Solvent Analysis

The sample of cannabis herb that is used for extraction usually contains chemicals and microbial impurities. The extracted oil ends up with residuals solvents, some of which are necessary for a higher efficiency of the drug while others would need to be removed to purify the medicine.

A headspace analysis is performed to determine the amount of residual solvent present in the mixture. This is done by putting the mixture into a dome-like cylinder and obtaining a small amount of the surrounding air through a syringe without sampling the extract itself.

This method lets the laboratory technicians evaluate and identify individual components, profile and characteristics of the liquid.

All samples must also be tested for any residue of pesticides. Marijuana is cultivated in a crop. As all kinds of grown foods that we consume get sprayed with insecticides and pesticides, so is the case with Marijuana crop.

Guidelines about the level of pesticide in Marijuana extract must be strictly followed by the testing laboratory.

Physical Contamination Test

This is a step wise process to ensure quality control of the medicine. The preparation, handling and packaging of the extract must be done on clean surfaces and technicians are required to wear gloves and masks at all times to avoid any physical contamination.

Microbial Testing

Samples of manufactured cannabis batches must also be analyzed for microbes and bacteria. During extraction, there is a small chance of developing microbial content, especially where water is involved in the process. The curing process must be thorough and efficient to remove any harmful organisms from the medicine.

Testing includes statistical sampling, testing for relevant microorganisms that are known to develop during manufacture and validation certificates.

In cases where microbial species of pathogens are detected in the sample, the laboratory must classify the sample as “failed” and label it accordingly in its certificate of analysis.

Potency Analysis

Cannabis extract potency relates to the percentage of cannabinoid that is present in the sample being tested. Cannabinoids include all the known varieties i.e. THC, CBD, CBG and CBN etc.

Each state has different requirements when it comes to listing of the cannabinoids on the label. While some states require labeling for the two main cannabinoids, others may require the percentage concentration of every known cannabinoid present in the batch.

Heavy Metals Analysis

Some states also require laboratories to label the presence of any heavy metals in the batch. Heavy metals include Arsenic, Cadmium, Lead and Mercury.

Presence of any such metals should be clearly labeled. Most states require that heavy metals content of the batch must be no more than a few micrograms per milligram of medicine. A sample with excess levels of heavy metals must not be sold as they can be potentially harmful to consumers.

Terpene Analysis

Terpenes are a group of hydrocarbons found in plants and oils. They give the characteristics of smell and flavor to plants and herbs.

Terpene Analysis is performed to measure the fragrance and flavor elements of a sample. State laws require that samples should be tested for the presence of terpenes and the concentration levels should be accurately labeled to one-hundredths of a percent on the

Cannabis Testing Standardization

Lack of regulations on medical marijuana testing can lead to discrepancies in potency data and give inaccurate information about the medicine. Some states, like New York and California, either have a standardized testing and labeling process or looking to standardize the process to build trust in the medical marijuana industry.

Like the state of Washington where a group of I-502 accredited laboratories are undergoing a “round robin” program to test the potency and chemical composition of an unknown cannabis sample, and then compare their results to check for discrepancies.

Leave A Comment

You must be logged in to post a comment.